Thermography allows to estimate the state of parts which constitute the electrical supply of an equipment. It may avoid production losses and it identifies elements which require a predictive maintenance.

- High voltage cells (open or equipped with infrared fixed lights)

- High voltage or low voltage transformers

- Power supply, u.p.s, plugs, filters

- Barring engine

- Circuit breaker

- Fuse

- Switch, thermal relays

- Low voltage distribution board

- Connecting box

- Cable path

- Etc...

|

|

Connection problem on a 20kV airline insulator... |

|

Problem on the current measure loop in a 20kV latticed with iron cell... |

|

|

Connection problem of the third phase at the side of 20kV of this transformer...

|

|

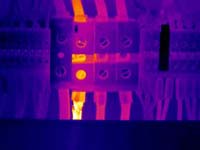

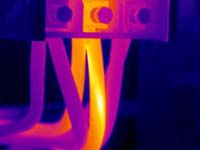

Problem on the middle phase behind this circuit breaker... |

|

|

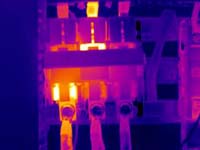

Internal problem at the contact point of the third phase of the contactor... |

|

Problem on the terminal of the left phase... |

|

|

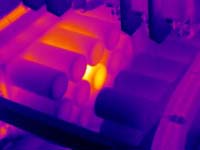

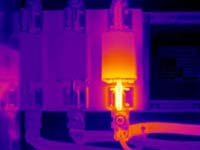

Connection problem between the jaws and the fuse... |

|

Other connection problem between the jaws and the fuse... |

|

|

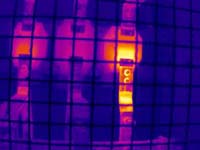

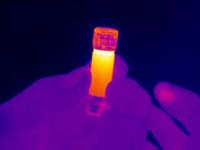

Internal problem of a fuse... |

|

Internal problem on the core of the central conductor... |

|

|

|

Internal defect of a power capacitor... |

|

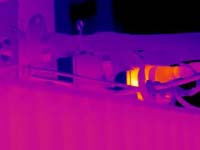

Overheating in the engine terminal box... |

|

|

|

Connection problem of a braided conductor wire... |